Speeches Shim

Short Answer

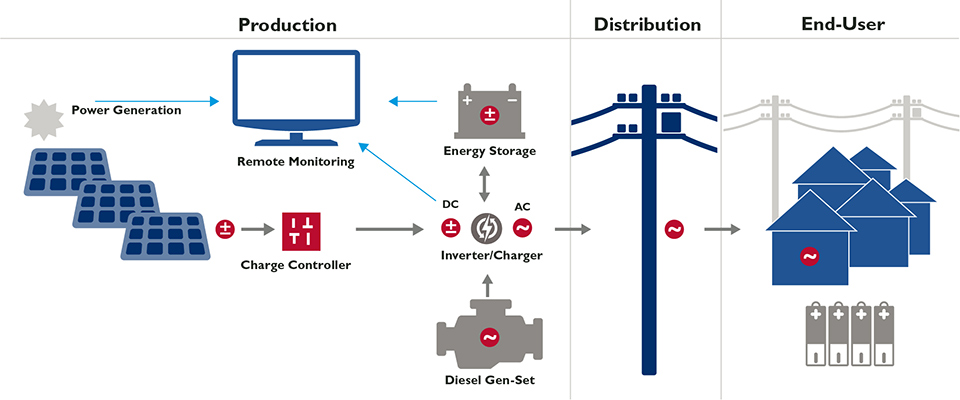

A mini-grid’s basic technical components are grouped into three systems:

Mini-grid Systems

- Production

- Generates electricity from either a single energy source or a mix of sources

- Distribution

- Moves electricity from the generation site to end users

- End User

- Provides connections that allow customers to use electricity

Each system includes varied components, which are based on available resources, desired services and user characteristics.

Further Explanation of Key Points

Production System

A mini-grid’s production system consists of energy generation technologies, inverters, a management system and sometimes storage (batteries). The production system determines the mini-grid’s overall capacity to provide electricity to end users.

Energy Generation Technologies

Mini-grid energy generation technologies can include diesel generators, hydropower systems, solar photovoltaic (PV) modules, wind turbines, biomass-powered generators and geothermal-powered generators. A mini-grid may use a single energy source or mix of sources (hybrid) that are either renewable or nonrenewable.

Inverters

Mini-grid production systems use power inverters when end users need a different type of electrical current than what the energy production technology generates. Some energy generation technologies produce direct current (DC) while others produce alternating current (AC). Solar power, for example, generates DC, whereas nearly all mainstream appliances require AC. So a solar-powered mini-grid serving households would need an inverter as part of its production system. Battery charging, on the other hand, requires DC power. An inverter would convert electrical current from AC to DC if the current were coming from a grid-tied (utility) system or from a diesel generator.

In an AC-coupled configuration with storage (a battery), the energy generation and storage systems each have their own inverter. These separate inverters connect to one another on the AC side of the system. Operators can use the battery inverter to control charging and discharging.

In a DC-coupled PV configuration, the energy generation and energy storage systems share an inverter. DC coupling can provide better performance; battery charging is more efficient when there are fewer power conversion steps.

Management System

Mini-grid production systems include management systems, which measure, monitor and control electrical loads. A charge controller, for example, connects between the solar panel and the battery or inverter/charger to prevent over-charging of the battery. Likewise, metering and monitoring equipment allow mini-grid managers to gather data about energy use across end users, which informs operational decisions. Management systems often couple computerized energy management tools with smart metering to optimize performance. Some management systems allow operators to control the system remotely, including shedding loads as needed.

Storage

Some mini-grid production systems require energy storage (such as batteries). Solar and wind resources, for example, are non-dispatchable. This means they only produce power when the renewable resource is available, not according to user demand. If end users require power on demand, the mini-grid must be able to store energy and supply it when resources are not available. Energy storage adds stability to the system by storing energy for peak consumption. Large mini-grid systems that run diesel generators continuously do not require batteries, but nearly all other mini-grid systems require some type of energy storage.

To optimize system performance, longevity and cost, project developers need to identify the most appropriate energy storage technology for their mini-grid. Lead-acid batteries are the most common, but fuel cells and advanced battery technologies—like lithium-ion, nickel metal hydride and sodium-ion batteries—are generally more efficient and last longer. Costs for these new technologies continue to decrease.

Large battery banks pose safety hazards. High concentrations of hydrogen gas can cause explosions, and leaks can cause electrolyte spills. Installers should locate batteries in well-ventilated locations such as utility rooms or outbuildings.

Purchasing and operating a battery can sometimes cost more than operating a diesel generator continuously, especially when operators are unlikely to maintain and use the battery correctly.

Distribution System

The electricity distribution system moves power from the energy production system to end users. The distribution system consists of distribution and/or transmission lines, transformers and the infrastructure to support the lines, such as poles. Lines can be overhead or underground; overhead transmission is most common because it is far cheaper to build.

The distribution system can use a variety of voltages, either AC or DC and either single- or three-phase power. Transformers change the AC voltage levels in a mini-grid network covering a large area. Step-up transformers increase the AC output voltage to transmit electricity more efficiently over a distance. Step-down transformers decrease the voltage from high- or medium-voltage transmission lines to 120 V or 220 V for residential use.

Transformers in AC mini-grids decrease distribution network costs and system losses. Distributing electricity at medium voltage allows systems to use smaller conductors, reducing cable costs. Higher voltage poses greater safety risks for operators and users, however, so operators need special training.

Different components have different efficiencies, so the choice of voltage, current and transformers impacts energy losses. Cost usually dictates which option project developers choose. DC is generally less expensive than AC, because AC requires power conditioning equipment. Developers should also consider the availability of appliances for different currents. Today the overwhelming majority of consumer appliances require AC; DC appliances are considered “niche” or specialty. In addition, the provision of “future proofing” of the network virtually always defaults to an AC-based system due to its ability to be expanded and grown as consumer demand matures and grows. Ideally the mini-grid will eventually be connected to the national grid, with minimal system or component replacements, but this would not be possible in a DC-based network.

End-user System

End-user systems provide an interface for end users to access, use and monitor electricity from the mini-grid. End-user systems should take into account consumers’ needs and energy uses. Businesses that are operating machinery for productive uses, for example, need different systems than households that use electricity for lighting and small appliances. The end-user system consists of connections to and from the mini-grid, systems to prevent electrical shocks and harm to both equipment and users and power consumption metering.

End-user systems provide information to end users, or consumers, that allow them to monitor their energy consumption, estimate the cost of their consumption and understand the current status of the system. They also provide useful data back to the system operator, reporting on consumption rate and timing, like when and how much energy is used. These data provide valuable feedback to system operators, which enables them to estimate and predict demand and consumption patterns. The data also allows regulators to establish tariffs that balance the needs of the operator and the consumer, while ensuring differing use cases are priced fairly and competitively. Finally, the end-user system provides important electrical bond and grounding mechanisms to ensure the safety of its users and protect valuable and expensive equipment.

Mini-grid enterprises rely on frequent, small payments from their customers, making metering, billing and collection time consuming. Innovative metering and payment systems automate these otherwise complex tasks. Individual meters (one per end user) provide the greatest degree of control over energy use. Meters can be pre- or post-paid; pre-paid meters typically are called pay-as-you-go (PAYG) metering.

Newer generation meters are typically considered “smart meters.” Although older, traditional meters are still in use, both have advantages and disadvantages.

Pre-paid (Pay-as-you-go) Meters

PAYG meters allow end users to pay for energy in advance. In some PAYG metering systems, such as with Kenya’s M-PESA, customers purchase minutes or quantities of electricity using mobile-phone-based banking. After a purchase, the customer receives a code via short service message text. The user then enters the code into the PAYG meter, which registers the credit. Other PAYG systems use scratch cards of fixed denominations, purchased at a local kiosk. The buyer scratches the coating off the card to reveal a code that, when keyed into the meter, updates the meter to indicate the new level of credit. As the customer uses electricity, the meter counts down the remaining credit.

PAYG meters benefit end users and utilities. Consumers with no credit history can gain access to energy. By showing expenditures in real time rather than in a single bill at the end of the month, PAYG meters allow users to budget for electricity more effectively. Customers often use electricity more efficiently when they can see the cost in real-time. In the United States, for example, customers with pre-paid electricity metering decreased their energy consumption by 11 percent. For mini-grid developers and operators, PAYG meters reduce payment collection costs and eliminate the risk of non-payment. When a user’s pre-paid credit is consumed, the meter turns off.

Following are illustrative examples of PAYG meter providers and mini-grid system manufacturers who use PAYG metering technology:

- CAT Project’s Bushlight India

- Circutor Electricity Dispenser

- Enèji Pwòp

- Gram Power

- Ideal Prepaid

- Inensus

- Lumeter

- Metermate

- SharedSolar

- Steamaco

Post-paid Meters

Post-paid meters were the standard technology in most countries until the 21st century. With post-paid meters, the utility company sends a meter-reader by each household monthly (or periodically) to determine how much energy is consumed. Then the utility sends the household a bill accordingly. Households using post-paid meters tend to consume electricity beyond their means as these meters provide little feedback at all.

Post-paid meters work poorly in places where consumers are not used to managing their consumption. This system discourages utilities from installing electrical services in areas in which consumers are unable to regularly pay for energy use or at all. Post-paid meters also require diligent record-keeping and billing along with a large number of meter-reader technicians who must travel regularly to monitor the meters of all the end users. Traditional meter readers also introduce the risk of corruption. For example, an angry household can convince a meter reader to take a payment in exchange for reporting incorrect information.

Smart Meters

Both pre-paid and post-paid meters can be “smart meters.” Smart meters offer advantages over traditional technology for both the consumer and the utility. By monitoring and transmitting frequent information, a smart meter allows the utility to better monitor consumption across the whole system, and provides the user information on their ongoing usage and estimated expense. Smart meters gather data on energy consumption and facilitate two-way communication between the energy provider and end user, usually using cell phone technology. For example, a smart meter installed on the side of a residence communicates wirelessly with the utility systems. Smart meters have several key advantages:

- Early detection of outages or other problems

- Automated remote monitoring and meter reading

- Pre-payment for energy (some types)

- Efficient load scheduling and limits

- Real-time updates on power delivered and remotely controlled load shedding

- Real-time theft detection

- Gateway to cloud-based remote communication

- Automated tariff modification for variable smart pricing and demand-side management

Smart meters do more than transmit payment and consumption data. Some metering systems can log and report power quality and reliability data in real time, which enables operators or technicians to address power quality issues before they become problems. Smart meters can even allow the grid operator to shut down troublesome loads before they jeopardize the entire system and cause problems for other consumers. These features can help grid operators deliver a higher quality of service to all customers.

Relevant Case Studies

Bamiyan Renewable Energy Program (BREP). BREP developed a large-scale solar PV mini-grid to replace diesel generators in Afghanistan’s Bamiyan region. As of 2017, the system was generating 1 MW of reliable electricity to more than 3,500 businesses, homes and government offices.

Resources

International Renewable Energy Agency (2016). Innovation Outlook: Renewable Mini-Grids.

This publication describes the current state of mini-grid technologies and areas for technical innovation. The report covers technologies that serve the following functions: controls, management and measurement; energy storage; energy conversion and energy consumption.

Comment

Make a general inquiry or suggest an improvement.