- Energy Home

- How We Work

- Programs & Initiatives

- EmPOWERing Women and Girls

- Competitive Energy Procurement

- Toolkits

- Powering Health

- Cooking Technologies and Fuels

- Energy Efficiency

- Climate Risk Management

- Mini-Grids

- Monitoring & Evaluation

- Resources

- Stories

Speeches Shim

The load and energy consumption profile of an off-grid health clinic helps in developing energy indices that can be used to compare its energy performance with that of similar health facilities.

An initial load and energy analysis of an off-grid health facility is a critical component to facilitate the design and operation of energy supply systems. When properly executed, a load analysis can yield valuable insights into facility energy usage that can help reduce energy costs, increase productivity, and protect critical assets.

A load inventory produces quantified estimates of a facility’s electricity load and consumption. These play a large role in choosing and sizing appropriate energy supply systems, such as batteries and photovoltaic (PV) panels. They can also be used to compare facility energy usage to benchmarks, such as sector norms, or similar facilities. Creating energy indices allows administrators to track and compare energy consumption by other performance indicators, such as the number of patients served.

Health Facility Load

Electricity loads are measured in Watts, which is a unit of power. The load of a particular piece of equipment, then, is the amount of electricity it requires to operate at any given moment. That electricity must be provided by the facility’s energy supply systems, which may be the grid, a generator, or an array of PV panels. Understanding equipment loads is, therefore, necessary to size a facility’s energy system correctly.

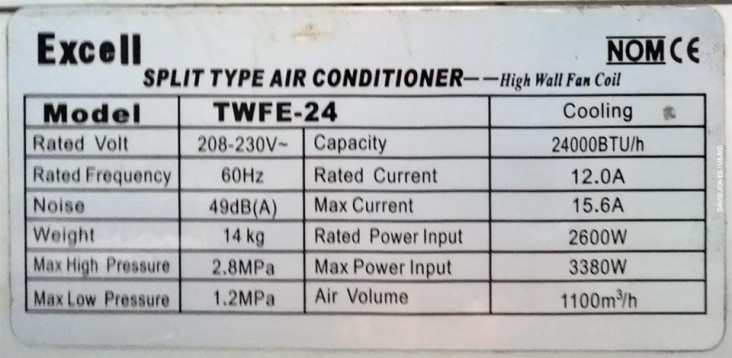

Load information can be gathered from multiple sources. Some equipment types have standard wattage values that can be assumed in most cases. Information on typical load values for a wide range of equipment can be found online. All electrical equipment (air conditioners, refrigerators, computers, lighting, etc.) should, however, have a label indicating at least its voltage and current and often other important information like wattage or cooling capacity. Finally, load can be measured using a voltmeter and ammeter.

Summing up the load values (in Watts) of all the equipment at a facility will yield the total facility connected load, which is the maximum amount of power the facility needs to operate all equipment at once. This figure can be broken down by load characteristics (end use or contact/no-contact), yielding, for example, the total lighting load or total no-contact load.

It is unlikely, however, that all electrical equipment at a facility will be turned on at the same time—different equipment operates at different times of the day. For this reason, a load profile is created. A load profile sums equipment loads based on the time of day that the equipment operates. An hourly load profile, for example, presents the total of all the loads operating during each hour of the day. The load profile approximates actual demand for electricity throughout the day.

During a facility’s normal operating hours, the load profile should show higher total loads, because computers, lab equipment, and other devices are being used. In the evening, or during off-hours, loads are reduced because the facility is supporting less activity. An essential tool for analyzing energy usage, the load profile indicates the actual demand placed on the energy supply and reveals the minimum and peak loads.

Energy Consumption

Electricity consumption is measured in Watt-hours, a unit of energy, or the total energy used in a given amount of time (e.g., daily, annually). Consumption is determined by multiplying each load by the number of hours it operates—the same information used to create the load profile.

For a health facility, different loads, such as lighting, laboratory equipment, vaccine refrigerators, air-conditioning units, etc., operate for different durations throughout the day. Some equipment operates more during the daytime than at night and vice versa. Accounting for the time of use of the loads throughout the day is an important step in developing a health facility’s energy consumption profile. This also helps with developing strategies for power supply options, such as solar power systems, battery backup systems, and diesel generators.

Energy consumption correlates directly with energy costs. Most electricity bills are charged in $/kilowatt-hour (kWh), a set cost per unit of consumption. Likewise, diesel generator fuel use corresponds to the amount of electricity consumed.

Energy Indices

An energy index is a measure of energy intensity that simplifies tracking and comparison of facility energy usage with similar facilities or within the same facility over time. Energy indices are usually calculated by dividing the facility’s energy consumption by some other indicator of facility performance or size. A common energy index is consumption per floor area, or kWh/m2; using this index, a facility can be benchmarked to other buildings, regardless of differences in size.

Other examples of useful energy indices for health-care facilities include kWh/number of beds, kWh/number of patients treated, kWh/local population, kWh/number of staff, and kWh/lab tests completed.

An energy index is also very useful when tracking facility consumption over time and allows for changes in activity level at the facility (e.g., patient visits, new treatment initiatives) to be factored into the comparison.

Comment

Make a general inquiry or suggest an improvement.